Is 3D Printing Good for the Environment?

Updated: Oct. 04, 2022

3D printers don’t just make cool products—they can also make a positive impact on the planet by reducing waste. Here’s how.

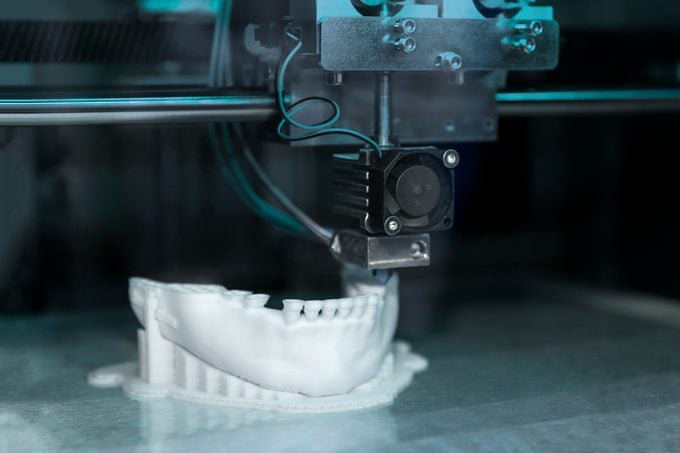

There’s a lot of buzz surrounding 3D printers right now—and for good reason. After all, anyone with a dream and a design can use them to create something cool. But they’re especially attractive to manufacturers, who see them as a way to not only lower costs and speed up production but also meet their sustainability promises. But how does 3D-printing products reduce waste and help the environment, exactly? And does it really live up to the hype?

The possibilities certainly seem promising, in terms of how 3D-printed products are made and the ability to troubleshoot problems when creating prototypes. This technology will also play a significant role in the future of recycling and energy usage. And that’s just the beginning. Still, experts warn that there are some potential downsides to this burgeoning technology, which currently accounts for just around 1% of the global manufacturing market but is set to explode over the next seven years, going from $18 billion in 2022 to $83 billion by 2029.

Let’s take a closer look at exactly what 3D printing can do for the environment and what it can’t … at least not yet.

How 3D printing is good for the environment

It reduces waste

Traditional manufacturing often doesn’t use materials efficiently. The process is generally subtractive, meaning that you start with a large block of material, hack away at it to create a product and then throw away the waste. 3D printing, on the other hand, is an “additive” process, building a product layer by layer. The printer follows a computer-aided design (CAD), leaving hollow spaces in the middle or wherever else material isn’t needed. It uses only the exact amount needed in the exact way, so there’s no need to carve or trim excess materials. As a result, there are exponentially fewer scraps.

According to experts, 3D printing in the construction industry can reduce waste by 95% or more. “Depending on the technology, it has the potential to unlock truly zero-waste construction, eliminating approximately 4.4 pounds per square foot, on average, that go to landfills [when building] a traditionally constructed home,” says Sam Ruben, co-founder and senior sustainability adviser at Mighty Buildings, a California-based 3D-printing construction company. Fewer leftovers headed to the landfill translates to fewer greenhouse gas emissions, fewer toxins leaching into the ground and less pollution—all of which can help slow climate change.

And the applications are endless in various manufacturing arenas, whether you’re building homes, furniture, cars, space shuttles or medical equipment. 3D printing also reduces waste before you even start creating a product because you can create more effective prototypes. Since a large portion of the design process takes place on the computer, with AI helping to produce incredible simulations, it is easier to identify which parts need to be improved and which might fail. As a result, you don’t have to go through quite as many materials (which will eventually get thrown out) before figuring out how to create the item you want.

It cuts down on shipping

The transportation sector is one of the world’s largest contributors of greenhouse gases. The maritime shipping industry, in particular, is responsible for at least 2.5% of the planet’s total carbon emissions, and that’s not even taking into account air and road travel. 3D printing could make a serious dent in this issue by reducing fuel usage.

In a traditional production situation, a product (and its assorted components) might be transported several times. It is usually made at a production company, often in another country, then moved to a local packaging company, and finally shipped to a store. That’s a lot of fuel used, not to mention exhaust released. But a 3D printer allows the product—including all the packaging—to be made locally. An item can be designed in one country, and then the design can be sent digitally to another for production.

Even better, “a company could invest in its own 3D printer and produce the [item] in-house,” says David Bourell, a professor of mechanical engineering and materials science and engineering at the University of Texas at Austin. By cutting down on the number of places an item has to be created and packaged, there’s less flying, shipping and driving. This can also help with supply-chain issues, since less would be produced and shipped from overseas production sites. Plus, Ruben adds, 3D printing allows manufacturers to use nontraditional materials that are locally sourced and more sustainable.

It can use recycled materials

The filaments and plastics used in 3D printing are strong and biodegradable, which reduces plastic waste. And that’s not the only type of recycled material that companies (and hobbyists) can use in 3D printing.

“This can be everything from using recycled plastic bottles for thermoplastic printing, to deploying waste like old wind turbine blades or glass,” Ruben says. “As we continue to see advances in recycling technology, we will see the types of printing that can utilize recycled materials expanding and moving ever closer to truly circular economies around 3D printing.”

Parts can be made to order

Need a single part for a product? No problem. What about a very specific one? 3D printing’s got you there too, since production can be personalized. This is another environmental win because it means companies don’t have to mass-produce items and waste materials. To put this into context, think about a building a house. A traditional wall would use wood, screws, drywall, tape, insulation, barriers and plates. If you were using a 3D printer for that house, you could create only the specific things you need for the project at hand—or print the entire wall with all the components. This also saves energy, fuel and production costs.

And according to All3DP, 3D printing has the potential to revolutionize affordable housing. Habitat for Humanity partnered with Alquist in 2021 to print a single-level concrete home, and it took only 12 hours to build. Yes, you read that right: 12 hours.

How 3D printing is harmful for the environment

There’s no denying that there are a lot of upsides to 3D printing, but the process is not entirely sustainable. “As with any technology, 3D printing is not a silver bullet,” Ruben says. “Though 3D printing holds incredible possibilities for improved sustainability, we are still seeing the use of materials such as virgin plastics and polymers and concrete, which are some of the biggest drivers of global greenhouse gas emissions.” Here’s a closer look at some of the current issues.

Many 3D-printing materials are plastic

As noted above, some of the materials may be recycled plastic, but in the end, it’s still a lot of plastic. “Many 3D-printing technologies use the exact same thermoplastic materials as traditional mass-production techniques, so that’s pretty much a wash for environmental impact,” says Denis Cormier, a professor of industrial and systems engineering at the Rochester Institute of Technology. “You therefore have an unfortunate choice between slower 3D-printing processes that use recyclable thermoplastic materials and faster 3D-printing processes that require disposal of hazardous waste.”

Plus, a lot of the plastic will still wind up in landfills someday. Think of it this way: If you can create cool products with just a click of a button, there is the potential for a lot of button clicking—and a lot of wasted products tossed in the trash.

It encourages people to create more prototypes

With prototyping comes wasted products, parts and iterations. “Failed prints are by far the largest downside,” says Nicole Bakker, a visiting researcher at the MIT Center for Bits and Atoms and founder of Circular Engine. “Another big one is the category of successful prints that lack functionality and over time lose their purpose. By having access to the technology, people are incentivized to create more stuff. Before you know it, you’ve created a bunch of waste.”

3D printing still uses electricity

While production times may be condensed, the amount of energy required to create a product is still high. That’s because 3D printing builds parts very slowly. “So, in general, we must invest a lot of energy in the manufacturing process over a relatively long period of time,” explains Bourell. “The result is a relatively low volume of final product.” Translation: It can take a lot of energy to create something small, so you’re trading one problem for another.

But the future is still bright

3D printing isn’t a static field. As scientists continue to work on this manufacturing marvel, they will develop new and better ways to create less waste and use less energy, making it more sustainable. And this has wide-ranging potential that could do everything from counteracting the negative effects of fast fashion to making space tourism more viable. In the meantime, says Bourell, anyone using a 3D printer should “consider the entire life cycle of a part to make the math work out in favor of it” before they press “print.”

Get Reader’s Digest’s Read Up newsletter for more tech, humor, cleaning, travel and fun facts all week long.

Sources:

- Fortune Business Insights: “3D Printing Market Size, Share & COVID-19 Impact Analysis”

- Sam Ruben, co-founder and senior sustainability adviser at Mighty Buildings, a California-based 3D-printing construction company

- S&P Global: “Your climate change goals may have a maritime shipping problem”

- David Bourell, professor of mechanical engineering and materials science and engineering at the University of Texas at Austin

- All3DP: “3D Printed House: 25 Most Important Projects in 2022”

- Denis Cormier, professor of industrial and systems engineering at the Rochester Institute of Technology

- Nicole Bakker, visiting researcher at the MIT Center for Bits and Atoms and founder of Circular Engine